The Torrefied Bio-Fuel Briquettes perfected on DOTE Technology

The science

behind

briquette production

(The Torrefied Bio-Fuel)

Based on researches conducted world-wide

The only machine perfected on DOTE Technology (Dry Oxidative Torrefaction Extrusion Technology)

Thermal degradation characteristics of biomass :

The main target is to upgrade solid biomass as an alternative to coal.

- Temperature between 25°C and 100°C: Moisture or free-water in the biomass is vaporized and the drying process is carried out

- Temperature between 100°C and 200°C: The weight loss of the biomass is fairly slight (around 1 wt%).

- Temperature between 200-500°C : Biomass thermal degradation and Devolatilization processes. The thermal degradation of the biomass becomes obvious and the weight loss is 19 wt%.

(Uniform and small particle size makes the process more efficient and can be completed within 0.1 seconds)

This is the reason we recommend raw material with particle size of 3 to 6 mm

Most of the Volatile Material is released and Fixed Carbon (FC) is retained in the solid residue

Source: Journal of Analytical and Applied Pyrolysis, 101 (2013), pp. 177-184

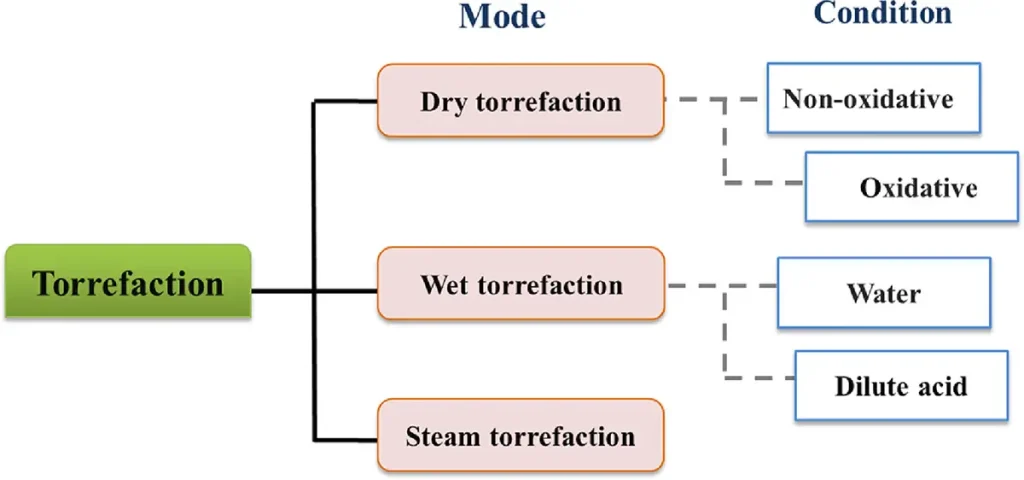

Torrefaction:

The purpose of the torrefaction process is to upgrade biomass and produce solid fuels with better quality

Dry torrefaction:

Comparison of non-oxidative and oxidative torrefaction.

Non-oxidative torrefaction | Oxidative torrefaction | |

Advantages | – Higher solid and energy yields – Easier in temperature control | – Lower operating cost (no N2 separation cost) – Lower heat supply – Faster reaction rate |

Disadvantages | – Higher heat requirement – Lower reaction rate – N2 should be separated from air | – Lower solid yield and energy yield (at high torrefaction temperatures above 500°C ) – More difficult in temperature control |

Source: Bioresource Technology, 127 (2013), pp. 318-325

Comparison of dry, wet, and steam torrefaction:

Empty Cell | Dry torrefaction | Wet torrefaction | Steam torrefaction |

Operating conditions | 200-300°C | 180-260°C | 200-400°C |

10-240 min | 5-240 min | 5-120 min | |

1 atm | 1-200 atm | 1-40 atm | |

Advantages | Easier operation | Lower reaction temperature | Suitable to wet biomass |

No post-drying | Suitable to wet biomass | No pre-drying | |

Continuous production | No pre-drying | Higher pelletability solid products | |

By-products in liquids | |||

Lower ash content in hydrochar | |||

Disadvantages | Pre-drying (We are providing dryer for this) | Post-drying | Higher energy consumption |

Comparatively higher ash content in biochar (Unique shape ensures complete combustion) | High-pressure operation | High-pressure operation | |

Corrosion of reactor by inorganic salts | |||

Challenge in continuous production |

Torrefaction of lignocellulosic biomass involves the degradation of hemicelluloses, cellulose, and lignin at different temperature stages.

- 150 to 200°C: Biomass initially degrades from due to dehydration and removal of light volatile

- At 200°C, the degradation of hemicelluloses occurs, including deacetylation and depolymerization reactions. The deacetylation leads to the formation of acetic acid, which would catalyze the further depolymerization of low-order carbohydrates, as well as condensation and degradation in lignin.

- At around 200°C The amorphous phase of cellulose starts to decompose to increase the relative crystallinity of biomass

- Crystalline phase of cellulose begins to decompose and the depolymerization of cellulose occurs at temperatures higher than 270°C

Source: Progress in Energy and Combustion Science,Volume 82,2021, 100887, ISSN 0360-1285

Lignin has a complicated and large structure compared to hemicelluloses and cellulose

- Lignin is an amorphous tridimensional polymer consisted of three basic units; They are p-hydroxyphenyl (H), guaiacyl (G), and syringyl (S) units, respectively.

- During biomass torrefaction, the softening of lignin starts at 160-190°C

- The cleavage of α- and β-aryl-alkylether linkages occurs between 150°C and 300°C

- The cleavage of aliphatic side chains occurs at around 300°C

- The cleavage of linkages leads to the removal of methoxyl groups (also called demethoxylation)

- Furthermore, the significant depolymerization occurs when the reaction temperature is beyond 300°C

Sources: Progress in Energy and Combustion Science, 62 (2017), pp. 33-86,

Renewable and Sustainable Energy Reviews, 38 (2014), pp. 594-608

Progress in Energy and Combustion Science, 53 (2016), pp. 41-79

Transformation of hygroscopicity to hydrophobicity

The raw biomass is hygroscopic owing to its inherent hydrogen-bonded to the hydroxyl groups of the cell wall components that can easily absorb the water. (30 to 60 wt%)

During Torrefaction, Hydroxyl groups of raw biomass are destroyed (due to dehydration and dehydroxylation reactions of hemicelluloses and cellulose in biomass) leading to formation of micropores

The formed tar condenses inside these micropores:

-lower the saturated moisture content in torrefied biomass

-inhibit the moist air passing through the solid.

-prevent the condensation of water vapor inside the pores

Dehydration + Dehydroxylation + Tar condensation transforms hygroscopic biomass into hydrophobic biochar

Sources: Energy & Fuels, 27 (2013), pp. 967-974

Bioresource Technology, 103 (2012), pp. 453-458

Test for hygroscopicity to hydrophobicity

Raw wood | Torrefied wood 230°C | |

Sessile drop technique | Around 65° in the beginning and becomes 0° at around 4 seconds | Keep for a long time and are always greater than 90° (Even reach 94° to 107°) |

Water droplet is absorbed rapidly | Water droplet stays on surface for long | |

Hygroscopic with contact angles (< 90°) -high wettability | Hydrophobic with contact angles (> 90°) -low wettability |

Sources: Energy & Fuels, 27 (2013), pp. 967-974

Bioresource Technology, 103 (2012), pp. 453-458